Overview

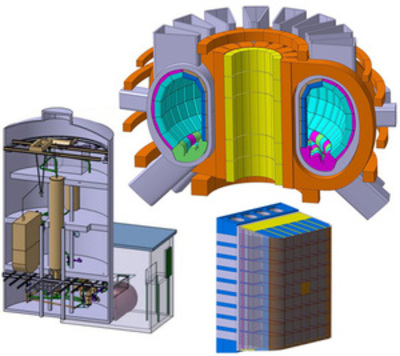

The KEK team is in charge of the design, construction, and operation of the experimental facility HELOKA, which is the largest high pressure helium loop in Europe. This helium loop is designed mainly for testing various components, which are cooled by high temperature and high pressure helium, for future fusion reactors. The Test Blanket Module (TBM) for ITER will be the first component to undergo a series of qualification tests under the reactor-specific operating conditions before it is delivered for testing in ITER. While developed mainly for testing components for nuclear-fusion applications, the HELOKA design allows the investigation of any other high flux helium-cooled components that are operated within the loop operating range.

Main areas of interest:

- Design of fusion and reactor specific multiscale experiments (IFMIF, HELOKA).

- Design of experiments and plants, supervision of manufacturing.

- Certification of manufacturing systems for reactor components.

- CAD and PDM implementation, administration and training.