ATEFA - AMTEC

ATEFA

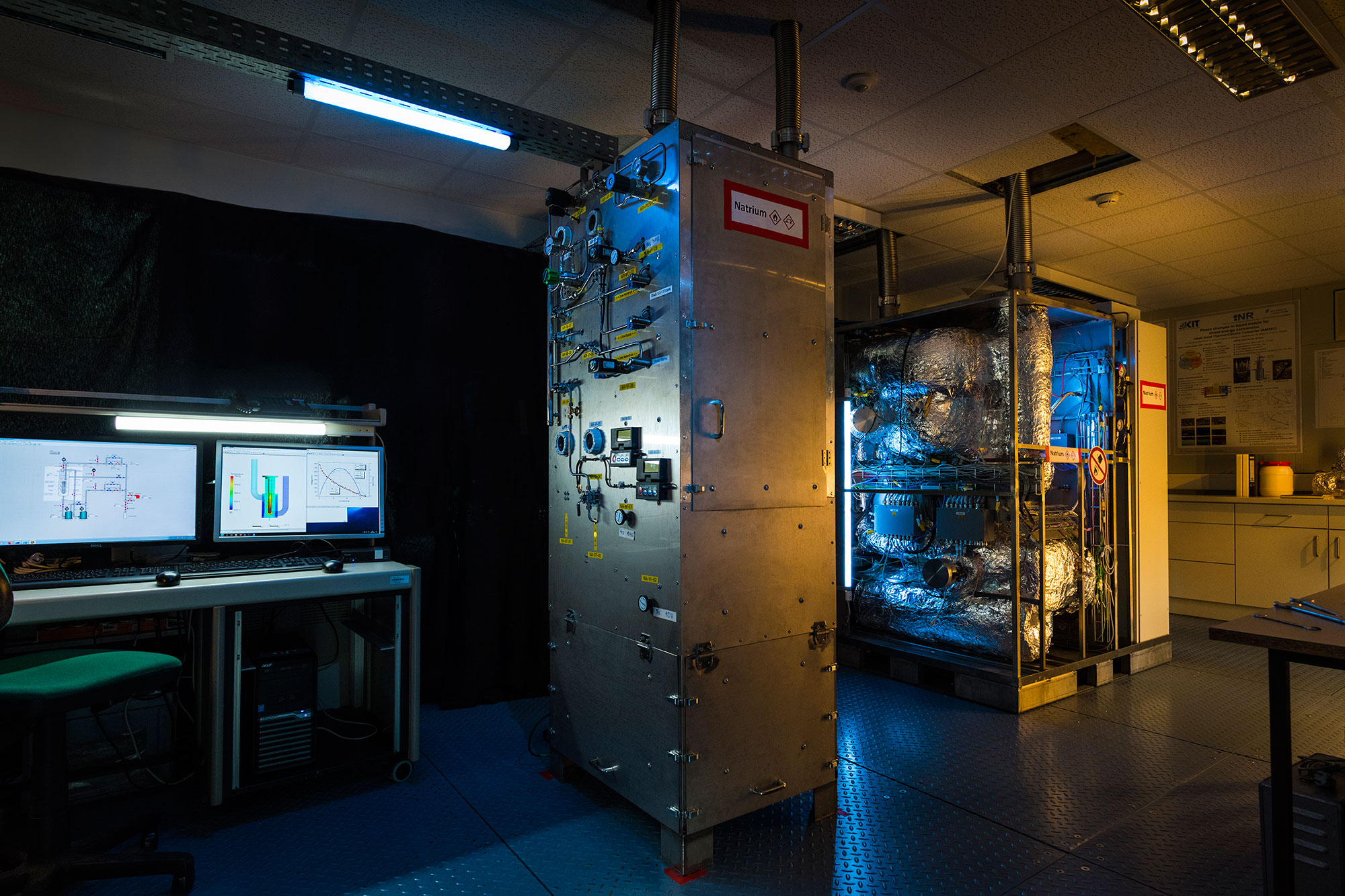

Direct energy conversion in combination with Concentrating Solar Energy (CSP) is a promising combination to achieve higher efficiencies. The Alkali Metal Thermal to Energy Converter (AMTEC) is a direct heat to DC electricity converter, which has been developed several years ago at KIT-INR. The ATEFA (AMTEC Test Facility, see Fig. 1) has been utilized for further investigation and development of the AMTEC converter. ATEFA is designed to operate in a wide temperature range of 600 – 900 °C and up to 0.5 bar overpressure. For safety reasons the facility is sheathed by stainless steel walls.

Fig. 1. ATEFA in AMTEC laboratory

The investigations performed up to now were focused on the development of metal-ceramic joints, analyses and tests of coating materials for the electrolyte (electrodes), tests of different materials and structures for the current collector, analyses of the electrochemical, electrical and thermal performances of the AMTEC cell, as well as comparison of the experimental data with numerical models.

AMTEC

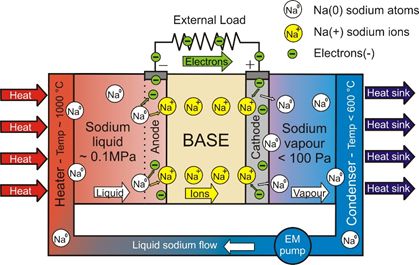

The Alkali-Metal Thermal to Electric Converter is a device for direct transformation of heat into electric energy. Most of them developed up to date, use sodium. Their key component is a beta”-alumina solid electrolyte (BASE). As a special feature of this ceramic, sodium ions can hop through its crystal structure so that it is permeable for sodium ions, but it is an isolator for electrons and neutral sodium atoms.

Fig. 2. Schematic of the AMTEC operating principle

In an AMTEC cell, the BASE separates the cell in two regions, both filled with sodium, as displayed in Fig. 2. One of them is heated – for example by solar power – up to a temperature range of ~600-1000 °C. The other region is cooled below a temperature of ~ 400 °C. In the high temperature region, sodium ionizes at the anode of the cell. The electrons are collected at the anode and directed to the cathode on the cold side of the BASE via an external load, where the produced electricity can be quantified. At the cathode, the recombination with the sodium ions transported through the BASE occurs and molecular sodium in vapour state is formed. The sodium is condensed and transported back to the hot side so that the cycle can restart. As a thermodynamic cycle, it corresponds nearly to an isothermal expansion of sodium between the two pressures on either side of the BASE. The theoretical value for conversion efficiency is about 40 %; however, presently ~ 20–25 % has been reached.

AMTEC has several advantages, such as a larger efficiency comparative to other direct converters, a large power-to-weight ratio, it is silent in operation and quasi maintenance free since no moving components are necessary. For commercial applications and increased performance, a modular assembly can be developed.

Though the principle of this converter exists since the 1960s, several issues are still open. The related experimental research in our institute aims at the development of improved designs for AMTEC cells to assess its usage in a concentrating solar power (CSP) plant as a topping system, increasing therefore the global efficiency of the plant. It addresses issues as material investigations, improvements, and development, studies of different metal-ceramic interfaces, a characterization of the BASE stability and improvement for long term operation, extension of the operational life time, as well as the increase of the efficiency of the AMTEC conversion process.

The studies benefit from our in-house experimental experience of about 15 years, a period in which several AMTEC prototypes were tested in our institute. Recently, studies were performed in the frame of the HGF LIMTECH (LIquid MEtal TECHnology) and HGF HEMCP (Helmholtz Energy Materials Characterization Platform) projects, in close collaboration with other institutes within KIT.

Publications

V. Heinzel, F. Huber, W. Peppler, H. Will. Technological tests with respect to the use of beta alumina in alkali-metal-thermo-electric converters (AMTEC). Key Engineering Materials, 59 & 60: 381 – 394, 1991

V. Heinzel, F. Huber, W. Peppler, H. Will. Development of an AMTEC, a converter of thermal to electrical energy, Materials Science Forum, 76: 261 – 264, 1991.

W. Hering, R. Stieglitz, T. Wetzel; Application of liquid metals for solar energy systems; EPJ Web of Conferences 33, 03003.1- 03003.7, 2012

N. Diez de los Rios Ramos, A. Onea, S. Scherrer, A. Weisenburger, and W. Hering. Direct energy conversion of heat to electricity using AMTEC, Proc. 5th Int. Youth Conf. on Energy (IYCE), 2015

Onea, N. Diez de los Rios Ramos, W. Hering, J. L. Palacios, R. Stieglitz, AMTEC clusters for power generation in a concentrated solar power plant, Magnetohydrodynamics 51 (3): 249 – 261, 2015

N. Diez d.l. Rios Ramos, A. Weisenburger, A. Onea, W. Hering, M. Stüber, S: Ulrich, R. Stieglitz, Technological developments in ATEFA for AMTEC research, 10th PAMIR Int. Conf. – Fundamental and Applied MHD, Cagliari, Italy, June 20 – 24, 2016

W. Hering, N. Diez d.l. Rios Ramos, A. Onea et al. Source independent power conversion system for deep space missions, 10th PAMIR Int. Conf. – Fundamental and Applied MHD, Cagliari, Italy, June 20 – 24, 2016

N. Diez d.l. Rios Ramos, W. Hering, A. Weisenburger et al. Design and construction of the ATEFA facility for experimental investigations of AMTEC test modules, Materials Science and Engineering, 228, 012014:1-14, 2017.

A. Onea, N. Diez D.L. Rios Ramos, M. Bologa et al. Considerations on thermal radiation of direct solar thermal power generation systems for space propulsion, Aerospace Europe 6th CEAS Conference, Bucharest, Romania, paper ID 194, 2017

A. Onea, S. Perez-Martin, W. Jäger, W. Hering, R. Stieglitz, Liquid metals as heat transfer fluids for science and technology, chapter 12 in Advances in “New Heat Transfer Fluids. From numerical to experimental techniques”, Ed. A. A. Minea, CRC Press, Taylor & Francis Group, 2017

N. Diez d.l. Rios Ramos. Technology developments for the Alkali Metal Thermal to Electric Converter (AMTEC) Test Facility. PHD Thesis. KIT, Germany. 2018

A. Onea, W. Hering, S. Perez-Martin, N. Diez d.l. Rios Ramos, R. Stieglitz, Numerical and experimental investigations of the temperature distribution in an AMTEC test cell, 11th PAMIR Int. Conf. Fundamental and applied MHD, Rems, France, July 1-5, 2019