SOLTEC

With the aim to develop, test and qualify innovative liquid metal components in Concentrating Solar Power (CSP) systems three high temperature liquid metal test facilities were developed at the INR in the framework of the HEMCP AMTEC Center (HAC), which is imbedded in Helmholtz Energy Material Characterization Platform (HEMCP). For the qualification of new materials for high temperature applications on a long time basis, the SOdium Loop for TEst materials and Corrosion facilities (SOLTEC) with different test sections were designed.

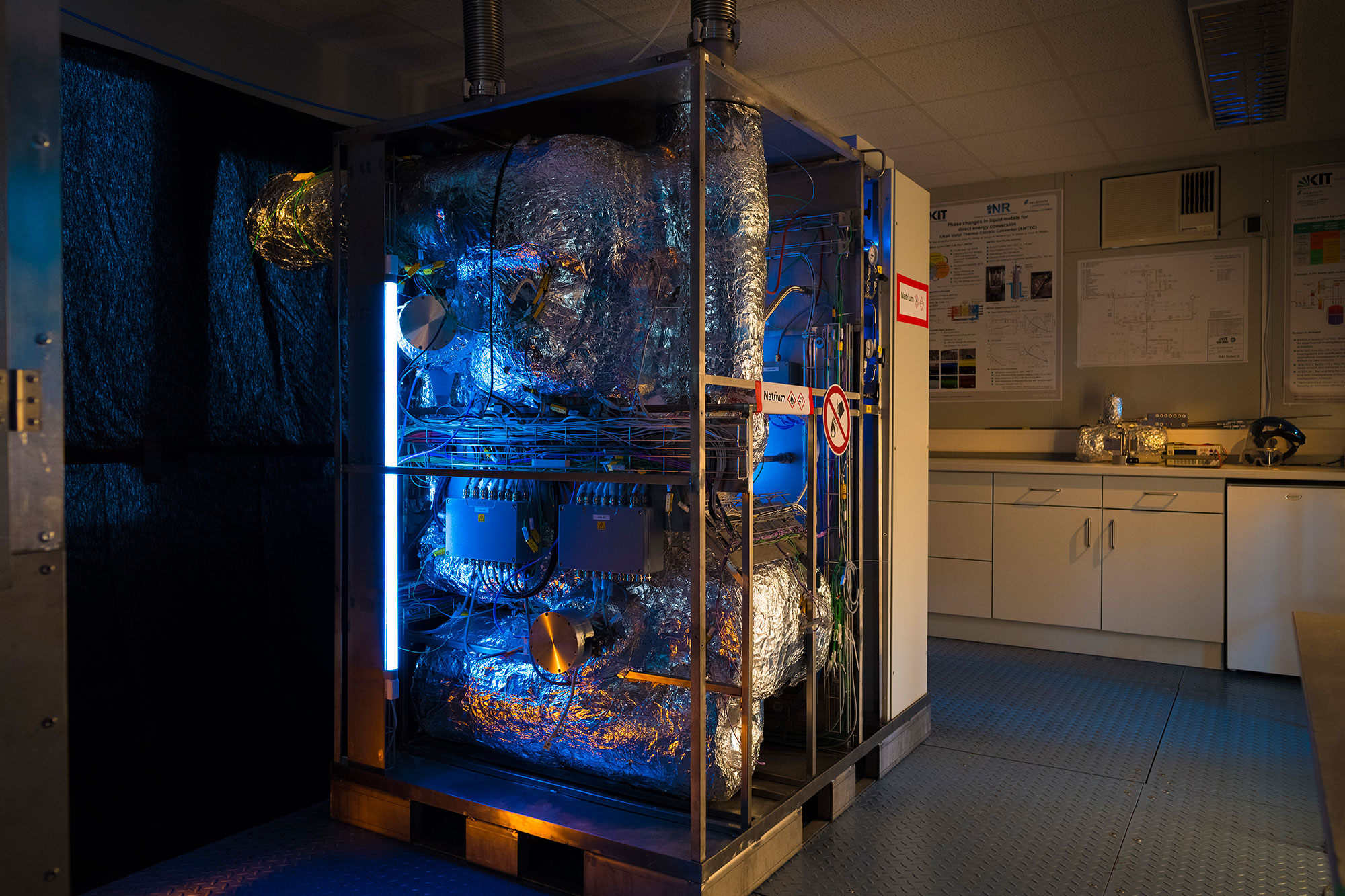

The core facility for SOLTEC-1 and SOLTEC-2 consists of two regions, the high temperature side with temperatures up to 1000 K connected to the test section and the low temperature side (£ 773 K), where the pump and the main components are located. Nickel based steels are used for the high temperature side, while conventional stainless steel is used for the low temperature side. At the interface between the high and low temperature side a Na-Na heat recuperator combined with a Na-air heat exchanger was installed. In all SOLTEC facilities, the sodium inside the test section is driven by a permanent magnet pump with a maximal mass flow rate of 300 kg/h. Sodium velocities up to 4m/s can be reached. Several safety measures were integrated and all facilities were designed to operate autonomously with passive fail safe option, allowing a fast emergency drainage. Each facility contains around 14 L of sodium.

Fig. 1. SOLTEC-2 facility

SOLTEC-1 serves for a unique in situ low cycle fatigue (LCF) investigation of new materials for high temperature applications, such as the tube receiver in Concentrating Solar Power (CSP) plants. The behaviour of innovative tungsten laminated compounds [3] and ductile refractory materials are planned to be investigated at high temperature in sodium environment. It was combined with a test machine and a high temperature vacuum oven allowing long term and fail safe experiments.

SOLTEC-2 is used for investigations of steel erosion and corrosion in flows of hot PbBi, Sn and Na under the environment of rapid temperature transients (ΔT~ 650-900°C). Long term investigation of the stability of protective surface coatings (in/outer surface) using pulsed electron beams (GESA-SOFIE) – Surface Optimization facility with Fast In-situ diagnostic Equipment) can be realised. Furthermore, investigations of innovative components such as flow sensors in temperature ranges up to up to 700°C were performed.

SOLTEC-SOLAM facility is employed for long term investigations of sodium based thermoelectrical converters, allowing the test of single cells, small and stacked modules. The experimental campaign will be focused also on the qualification of metallic/ceramic materials and joints for such converters. The test side of SOLTEC-SOLAM is layout up to 1220 K, while the cooling side is held below 773 K. The main sodium loop of the facility is used also for experimental tests of innovative receivers for applications in the CSP plants, while the by-pass loop of the facility is used for tests of the thermoelectric converters.

All facilities can be used also for experimental tests of components and specific instrumentation for high temperature applications using sodium.

Publications

A. Onea, N. Krauter, W. Hering, S. Lenk, S. Ruck, R. Stieglitz, G. Gerbeth, Experimental investigations and qualification of innovative flow sensors in the 1000 K SOLTEC-2 sodium loop, 28th SolarPaces 2022, New Mexico, USA, 27-30.09.2022

A. Onea, L. Spanu, W. Hering, R. Stieglitz, Heat transfer investigation of the sodium flow in the 720°C SOLTEC facility, 16th Int. Conf. on heat transfer, fluid mechanics and thermodynamics HEFAT-ATE, paper 07, 2022

A. Onea, W. Hering, S. Ulrich, M. Rieth, A. Weisenburger, J. Reiser, S. Lenk, T. Röbert, S. Vielhaber, S. Baumgärtner, R. Ziegler, R. Stieglitz, Innovative 1000K sodium loop for qualification of new materials for applicatons in CSP field, AIP Conf. Proc. 2445, 020010, 2022

A. Onea, R. Fetzer, F. Lang, A. Weisenburger, W. Hering, J. Fuchs, R. Stieglitz, G. Müller, Thermocycing tests by inductively heated sodium in the high temperature SOLTEC-2 facility, 27th SolarPaces 2021, online conf.

W. Hering, A. Onea, A. Jianu, J. Fuchs, Th. Schaub, A. Weisenburger, S. Ulrich, R. Stieglitz, Facilities to investigate sodium and materials behaviour up to sodium boiling, Proc. ICAPP 2020, paper 20205, 2020

W. Hering, M. Böttcher, J. Fuchs, A. Onea, S. Ulrich, R. Stieglitz, Materials and systems for liquid metal based CSP 2.0, AIP Conf. Proc. 2303, 050002, 2020

A. Onea, W. Hering, A. Weisenburger, S. Vielhaber, O. Albrecht, R. Stieglitz, Initial tests of the SOLTEC-2 high temperature sodium facility for corrosion analyses, 11th PAMIR Int. Conf. – Fundamental and applied MHD, 2019, Reims, France

W. Hering, A. Onea, A. Jianu, J. Reiser, S. Ulrich, R. Stieglitz, Liquid metals, materials and safety measures to progress to CSP 2.0, AIP Conf. Proc. 2126, 08000, 2019

S. Antusch, J. Reiser, J. Hoffmann, A. Onea, Refractory materials for energy applications, Energy Technol. 10.1002, 2017

A. Onea, W. Hering, J. Reiser et al., Development of high temperature liquid metal test facilities for qualification of materials and investigations of thermoelectrical modules, IOP Mat. Sc. Eng. 228:012015.1-9, 2017

W. Hering, R. Stieglitz, Th. Wetzel, Application of liquid metals for solar energy systems, EPJ Web of Conferences 33:03003.1–03003.7, 2012