Magnet Safety

1. Insulation failure behavior at high temperatures

The insulation properties at elevated temperatures are decisive for the development of an accident as the possible current path is important e.g. for the ignition and extinction of arcs. However, most data are only available up to room temperature. For this reason, small experiments have been performed with ITER similar insulation up to 1200K to measure thermal and electrical conductivity.

Another point presently under discussion is the failure behavior of the insulation in the vicinity of molten conductor (copper) or steel conductor jacket.

To estimate the interaction between the cable insulation, the steel jacket and the copper part of the conductor experiments up to steel melting temperature are prepared with different samples of the insulation and the surrounding material.

The insulation consists of 4 to 5 layers of fiber-glass cloth made from R-glass, which are soaked with araldite epoxy resin. Between these layers single Kapton (TM) polyimide foils are placed. The experiments are made in a furnace with reducing atmosphere and an additional heating system. Thermocouples and a resistance measurement are used for instrumentation.

Results: While the carbon-hydrogen components transform at about 350°C into conductive carbon material which disappears again at about 900°C, the R-glass part of the insulation is able to withstand temperatures close to steel melting temperature.

|

| First insulation failure test experiment: The insulation sample is sandwiched between a copper plate and a steel plate and placed in a ceramic pot inside the furnace. The ceramic pot has an additional heater at its lower side that cannot be seen in the picture. The four insulated wires are used for the resistance measurement, the single not insulated wire is a thermocouple. For the experiment, additional ceramic plates and pots are placed above the sample to reduce radiation heat losses |

2. Arc propagation along insulated conductors

The VACARC (VACuum ARC) experiments continue the investigations to busbar arcs under more realistic vacuum conditions and at enhanced power capabilities. The target is to find out about the characteristic behaviour of this kind of arcs and to support the development of a numerical model for busbar arcs in the frame of the MAGS code system.

In VACARC, a video camcorder and a high speed camera are used for visual observation. Arc voltage and current are measured and recorded by a PC based data acquisition system. Meanwhile more than 100 successful experiments were carried out with arc currents up to 1500A and arc powers up to 180kW. The model conductors used are scaled vs. ITER at 1:7, 1:4 and 1:3. However for 1:3, the available power converter is not able to simulate full ITER operation current.

It was found that arcing always destroys the complete busbar cross section, the relative strength of the ITER TF busbar insulation excludes hypothetical fast propagation modes that cut only the insulation while the metal core remains basically intact. The strong insulation also showed a considerable impact on the arc shape and power as well as on its burning direction. These observations had to be taken into account for modelling.

The calculation model gives satisfactory results in calculating the available VACARC experiments. In the next step, the similarity of the experiments to a real ITER busbar arc accident scenario will be further enhanced by changes to the experimental setup. The validity of the model at these modified conditions will be checked and - if required – the model will have to be modified for different arc behaviours.

|

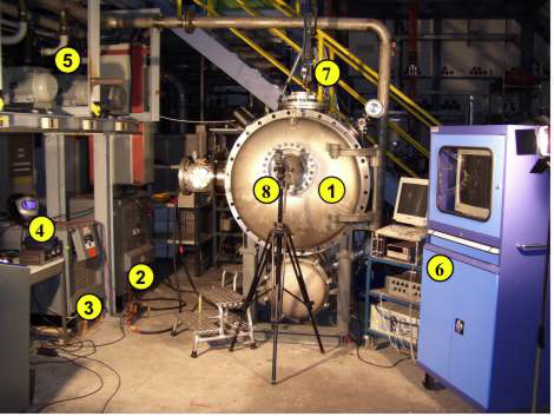

| VACARC device for scaled experiments to arcs at ITER busbars. The components are: 1. Vacuum vessel, 2. 120kW DC power converter, 3. 20kW DC power converter, 4. Control unit, 5. Vacuum pumps, 6. Data acquisition, 7. High-speed video camera, 8. Video camcorder |

A video shows a VACARC experiment that simulates the arcing of a busbar after quench (loss of superconductivity) and melting failure that may happen if the multiple safety precautions should fail. The scale with regard to ITER is 1:7. The arc starts to burn inline between both ends until at a certain length, it splits into two arcs in series while the current flow between the arcs goes through the conducting (steel) structures. The steel structure that simulates the separation plate between the incoming and the outgoing busbar inside their common feeder line is heavily damaged. The experimental verification of features like this assumed splitting behaviour is one of the important targets of the VACARC campaign.

Publications